Estude fácil! Tem muito documento disponível na Docsity

Ganhe pontos ajudando outros esrudantes ou compre um plano Premium

Prepare-se para as provas

Estude fácil! Tem muito documento disponível na Docsity

Prepare-se para as provas com trabalhos de outros alunos como você, aqui na Docsity

Os melhores documentos à venda: Trabalhos de alunos formados

Prepare-se com as videoaulas e exercícios resolvidos criados a partir da grade da sua Universidade

Responda perguntas de provas passadas e avalie sua preparação.

Ganhe pontos para baixar

Ganhe pontos ajudando outros esrudantes ou compre um plano Premium

Comunidade

Peça ajuda à comunidade e tire suas dúvidas relacionadas ao estudo

Descubra as melhores universidades em seu país de acordo com os usuários da Docsity

Guias grátis

Baixe gratuitamente nossos guias de estudo, métodos para diminuir a ansiedade, dicas de TCC preparadas pelos professores da Docsity

flotação de xarope de usina de açúcar

Tipologia: Notas de estudo

1 / 10

Esta página não é visível na pré-visualização

Não perca as partes importantes!

Tongaat-Hulett Sugar Limited, La Lucia

Tongaat-Hulett Sugar Limited, Felixton

polyelectrolytes with a higher degree of hydrolysis do give 90 ~---,---'~---r----r--r--r---.---r--r----, better results.

x

x

x 65 ex Syrup

o 60 ex Syrup

50

80

co 70 o^ > E ~

-... ' ii

t-

88, 78, 77, 80, 62, 33, 33, 39,

Av. turbidity removal %

50 100 200 300 400 500 600 800

Phosphate dosage (mg/Q)

Effect of phosphoric acid/lime addition on turbidity removal

100 r---_r---r----_r--~r----r--..,

Table 1

90

40 L-.L.-.L--..L...-..J.-..J.-....L..~...L.....L.....J

Temperature ee) FIGURE 2 Effect of temperature on turbidity removal.

From Figure 2 it can also be inferred that turbidity re- moval is independent ofthe brix and viscosity of the syrup.

that of 60' brix syrup used in the results shown in Figure

The effect of settling time in the laboratory test was in- vestigated. This showed that there was a tailing-off of % turbidity removal between 10 and 15 minutes, and that a retention time above this was unlikely to lead to improved results. It has been found in refinery phosphatation that it is nec- essary to employ dissolved air flotation rather than the sim- pler dispersed air flotation process." Again, laboratory trials indicated that there was no advantage in dissolved air flo- tation and, if anything, the dispersed air flotation gave better results.

5 30

0L.--I.. L...-...L..__--l ....L.. __-J o 10 15 20 25 Flocculant dosage - ppm on brix

FIGURE 1 Turbidity removal measured in the laboratory as a func- tion of flocculant dosage.

70'

10

30

Temperature was found to have a significant effect on tur- bidity removal. This is shown in Figure 2, which indicates that a progressive improvement is obtained up to 85 'C, at which point the effect of temperature levels off.

20

co 60

o E e ~ 50 ' :e::J t-

at the correct density level, with the minimum of inlet energy so that turbulence is not created. The depth of the clarifier is important only in providing sufficient height to be able to maintain separate froth and clear liquid zones. Flotation cells in refineries have been built in depths ranging from 0,25 to 1,5 m and Saranin- suggested that a depth of the order of 0.9 m could be optimum. What is more important he suggests,is that sufficient cross-sectional area should be provided to facilitate separation of the scum and that the depth should be fixed by the required retention time.

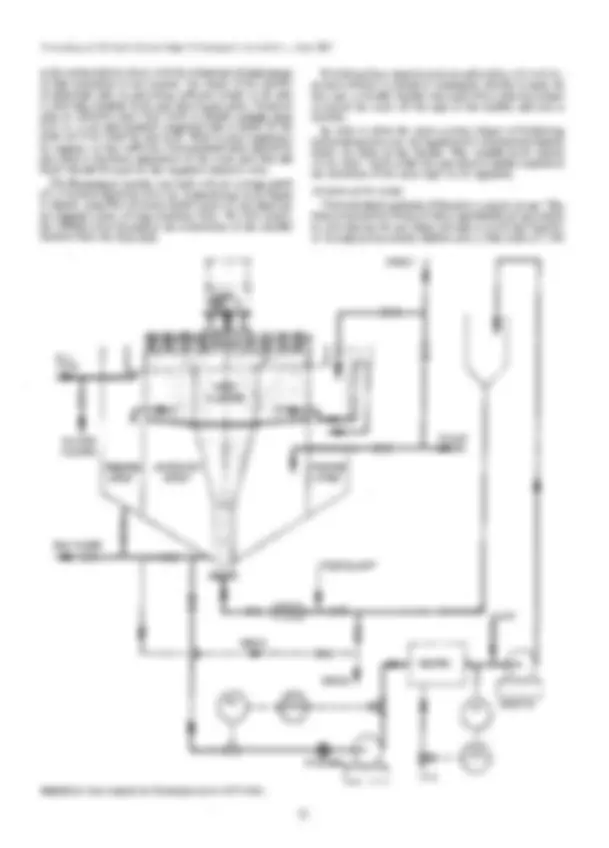

The Empangeni clarifier was built with an average depth of 1,5 m and a diameter of 4,1 m. A sketch is given in Figure

Providing these requirements are adhered to, it is not im- portant whether a round or rectangular clarifier is used. In this case, a circular clarifier was used with a rotating scraper to scrape the scum off the edge of the clarifier and into a launder. In order to allow the scum a certain degree of thickening before being removed, the liquid level is maintained slightly below the sides of the clarifier. The variable level control on the clear liquid outlet was provided to enable control of the thickness of the scum layer to be regulated.

Aeration of the syrup There are three methods of flotation currently in use.' The first is dispersed air flotation where gas bubbles are generated by introducing the gas phase through a revolving impeller or through porous media. Bubble size is of the order of 1 000

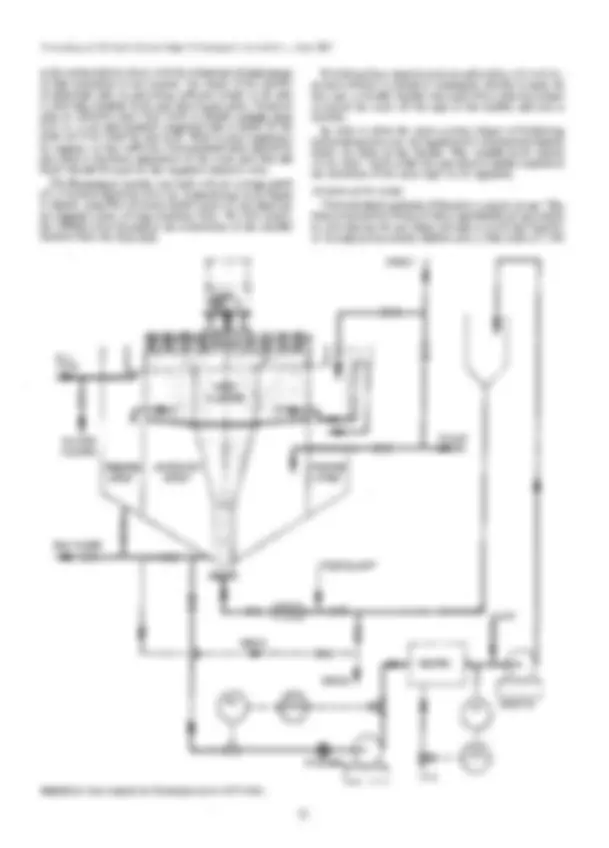

MJ. TANK

OLIVER FILTERS TREATED SVRUP

PAN FLOOR

MIXER

REHEL T

SYRUP

TREATED SYRlW

FLOCCULANT

AIR

CRAIN

CRAIN

FIGURE 5 Flow diagram for Empangeni syrup clarification.

HEATER

AERATOR

microns in diameter. The second is dissolved air flotation, where bubbles are produced as a result of the separation of the gas from a supersaturated solution. Average bubble sizes are smaller and range from 70 to 90 microns. The third method is to produce gas bubbles by electrolysis. Under th~se circumstances, the bubble size can be smaller than 50

The third method mentioned above was found to be im- practical in the laboratory. It might be expected that dis- solved air flotation should be more efficient than dispersed air flotation in that the bubbles are smaller and better dis- persed within the liquid. However, the simple aeration pro- cedure used here must be classified as dispersed air flotation. Dispersed air flotation is commonly achieved by injecting air into the suction side of a pump operating at high speed. However, this process has its limitations. If more than about

the pump.' In addition, only about 40 % of air injected into the suction of a pump is dispersed in the liquid, and the remainder consists oflarge bubbles which cause undesirable turbulence; thus it was necessary to install a small air release tank immediately before the clarifier. The requirements of the system should be to add the cor- rect amount of air to the suspension as well as to ensure a good dispersion of bubbles throughout the suspension. Initially, air was introduced into a pump running at 2- pole motor speed. Better results were subsequently achieved when a separate aeration pump was introduced. This was specially designed with radial fins and blades in the volute

to ensure considerable shear, thus achieving the necessary air dispersion.

The flow diagram of the system used is shown in Figure

Operating Results

The turbidity removal achieved over the two seasons for which the syrup clarifier operated, are shown in Figures 6 and 7. Initially, turbidity removal was low, but it can be seen how it increased as design and operational problems were

100 ....... ------.

90

80 %^ Turb.^ Removal

Sugar Pol

(ij

o E 50 e ...^ >-

~ 40

I-

20

10

o

oc,

25 30 35

o (^5 10 15 ) FIGURE 6 Operational results at Empangeni, 1981/82 season.

o. 35 r-----r---.,..-----'T--......---r----.----r--~--...,-_,--_r-.........,

0 e Before Modification

"

K After Modification

(^61) ....... Cl .s c (^0) 0. °i... ...c Q)o C 0 o E0. ::J £ :.J

o 15 30 45 60 75 90 105 120 135 150 165 180 Time after addition of tracer (mins.) FIGURE 8 Residence time distribution of syrup measured in the Empangeni syrup clarifier before and after modification to the offtakes.

Boiling down tests were also undertaken on the second week molasses composite samples. The final target purity from these tests was not found to be significantly different. Although no significant difference in target purity differ- ence was recorded, a higher molasses brix was generally ob- tained with the clarifier on. The reason for this is evident in Figure 9, which shows that the operation of the syrup clarifier gave a decrease in final molasses viscosity ranging

content. Thus the mill had been able to take advantage of the lower viscosities either by boiling higher brix masse- cuites or using less steam and water on the centrifugals. A series of factorial tests was carried out in 1982, to in- vestigate the effect of air quantity, temperature and polye- lectrolyte dosage on performance. Provided the minimum quantity of air was introduced (of the order of 0,04 rnvm! syrup), the effect of quantity of air seemed to be insignificant. However, temperature was found to have a very significant effect, as established in the laboratory. Also, better results were obtained with 30 ppm flocculant on brix, rather than 10 ppm, although this difference disappears at higher tem- perature. These effects are shown in Figure 10. In general, it was found that the syrup clarifier was always able to achieve the same degree of turbidity removal as that obtainable in the laboratory. Subsequently, it has been found that this provides a useful check as to whether the plant syrup clarifier is performing as well as it should by com- parison with the results obtainable in the laboratory. The scum from the syrup clarifier was generally returned to mixed juice. Scum quantity varied considerably, but was

of the order of 5 % by volume. A trial was undertaken where the scum was returned to the filter muds. However, this overloaded the filters and led to a higher pol loss in cake and so this was subsequently discontinued. Empangeni mill was closed down during 1983. Some per- formance results are given in Table 3. The syrup clarifier enabled Empangeni to produce consistently good quality sugar meeting VHP specification and for the first time in many years to achieve molasses exhaustion results compa- rable with the best mills in the industry. Since Empangeni cane was to be delivered to the new Felixton mill, it was felt to be essential to install a syrup clarifier at Felixton II as well. Table 3 Factory performance results at Empangeni 1980/81 1981/82 1982/

EM Industry EM Industry EM Industry

Sugar pol 99,32 99,40 99,17 99,38 99,45^ 99, Export sugar: Colour a*c 560 0,49 0,30 0,47 0,26 0,29^ 0, Ash 0,19 0,12 0,18 0,15 0,16 0, Boiling House Recovery 85,0 87,5 85,7 87,7 86,5 87, Tons sugar- Refinery 66300 93325 50718 Export 6246 7125 66088 MJ Purity 83,3 84,8 84,2 85,7 84,0 85, RS/Ash ratio 1,0 1,1 0,9 1,1 0,8 0, TPD 9,4 6,7 5,5 4,2 3,9 3, Syrup clarification No (^) - Partial (^) - Yes (^) -

90 100

o

FLOCCULANT a 10 ppm on br1x

o

ox

40

o"--........---a..........-->-'--........---a..........-->-"--........---a._.........--o 30

10

x 30 ppm on br1x

50 60 70 BO Temperature ('C)

FIGURE 10 Effect of temperature and flocculant dosing level on performance of the Empangeni syrup clarifier,

100

90

80

70

0 E ~ .!:^ >- (^50) ' :e~ l- '#. 40

30

20

(^75 7677 78 ) % Dry solids

FIGURE 9 Final molasses viscosities measured at Empangeni during the 1981/82 season.

200

1600

600

1800

400

2000

oN ...<ll Q) Ul 1200 ' e:. .~ Ul 1000 oo Ul :> 800

Further Experience with Syrup Clarification

A small syrup clarification system was installed in the old Felixton mill, shortly before it also closed, during a period of extremely poor cane quality occasioned by a drought. This was done quickly and at low cost, but since scum removal was purely by overflow and not with the aid of the scraper mechanism, results were somewhat below that achieved at Empangeni. A 45 m- syrup clarifier, based on a 20 minute residence time, was installed at the new Felixton mill. Details of the design and installation were very similar to that employed at Empangeni. However, a separate polyelectrolyte system was installed so that different flocculants can be used for juice and syrup clarification. In addition, a plate heater was installed to heat the syrup up to 85 'C immediately before the clarifier. Unfortunately this plate heater has been plagued by blockage of the channels in the plates, due to the fact that small quantities of fibrous bagasse are present in the syrup and form a mat in the inlet ports, effectively blocking the heater. Thus, for most of the time, the syrup clarifier has operated at a temperature of around 58 'c. Figure II shows turbidity removal achieved at Felixton II during a period when attempts were made to optimise the operation of the clarifier. Once attention was given to proper

were achieved. Laboratory tests during this period indicated

bidity achieved in the plant is only 80 % of that obtainable

that achievable at 85 'c. Thus it appears that the lower tur- bidity removal which had been achieved at Felixton is due largely but maybe not entirely to the lower temperature. Various options for screening before the plate heater have been investigated at Felixton, and during the comingseason it is anticipated that temperatures will be up at 85 'c. In spite of the fact that turbidity removal is lower than it should be at Felixton, no problem has been experienced in making VHP specification sugar, even when mixed juice purities have been as low as 75. Although it is believed that the continuous A-pans also assist in reducing sugar colour, the syrup clarifier has ensured that sugar quality has been con- sistentlyacceptable. During a period of two weeks, the syrup clarifier was shut down to see whether it had any influence on undetermined loss. No effect could be detected, but there was an immediate effect on sugar quality. Sugar colour re- corded at the Hulett Refinery during this period is shown in Figure 12. The increased colour can be shown to be sta- tistically significant at the 99 % confidence level. Experiments have also been undertaken at Felixton to in- vestigate the method of air addition. A simple sparger in- stead of the dispersing air pump has been investigated. Although the simple sparger appears to give the same kind of turbidity removal, the appearance of the scum suggests that the aeration pump system should give much better re- sults. This will be repeated once higher temperatures have been achieved, and on different qualities of syrup.

2000

1500

E c

oN '<t

(^10) .. 1000 ~ o < o

Syrup Clar Off

oL-...L------J'-----.£---J,~____L__..........__~.,....-.........--....L.---....., o

500

FIGURE 12

TREATED SYRUP OUTLET

LEVEL

IN-LINE MIXER

DRIVE

OUTLET

SYRUP OUTLET

POLYELECTROLYTE INLET

~

-f--.....-. RAW SYRUP INLET

FIGURE 13 Sketch of the syrup clarifier installed at Triangle, Zimbabwe.